In the dynamically landscaped technology, where innovation is the heartbeat of progress, Formlabs recently launched Form 4, a 4th generation desk resin 3D printing, a game-changing evolution in a rapidly evolving field of technologies. In an exclusive conversation with Amod Satarkar and Ramnish Sharma, they elucidated the revolutionized journey of 3D printing, showcasing the disruptive potential of Form 4 and capturing their thoughts on the shifted technology!

Form 4 emerges in 3D printing as a progress of evolution from regular print techniques. Formlabs initiated the change of the basics of 3D print technique with an uncompromising commitment to professionalism, dependableness, and the ability to reproduce without compromise.

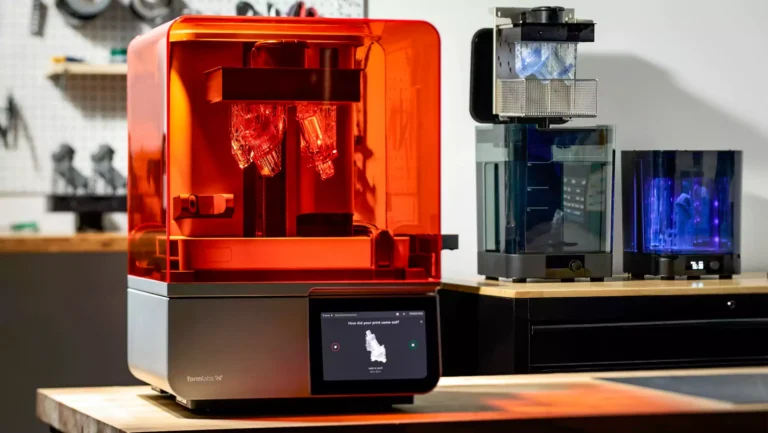

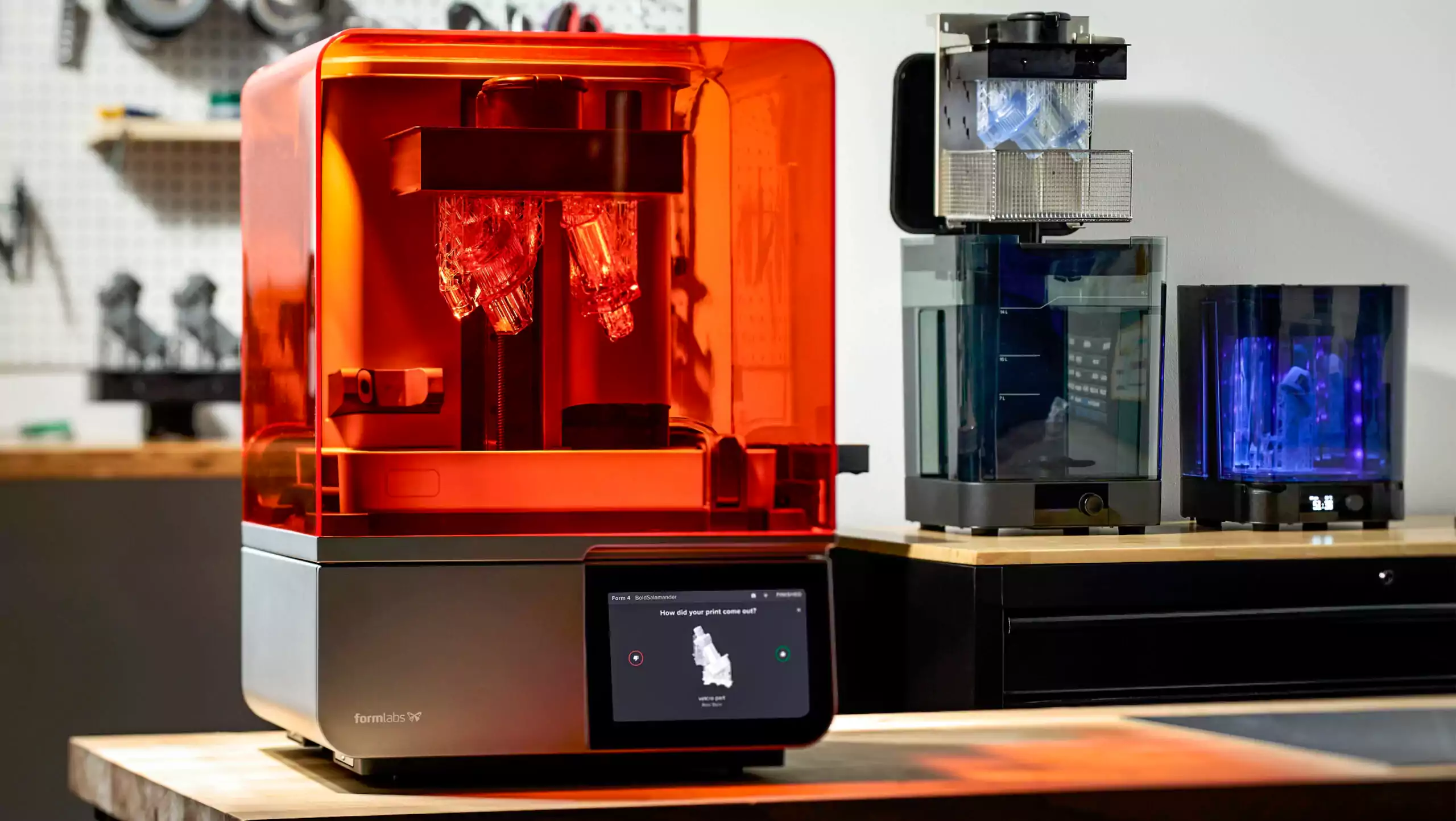

Formlabs Form 4

The Form 4 is an incredibly fast masked SLA 3D printer that pairs an extensive materials library with a dependable, precise print engine. Transform your ideas into reality quicker than ever with its user-friendly workflows, exceptional reliability, and outstanding part quality.

Major Transformation:

The motor vehicle and space industries saw a massive transformation in the prior ten years because 3D printing spread to various sectors. Technology made affordable ‘n accessible by Formlabs, sparkin’ a widespread acceptance in consumer good, electronic, medical, ‘n other industries!

LFD Technology:

The basis of Formlabs Form 4 is the innovation of LED-based LFD (Low Force Display Stereolithography) technologies, which beat their predecessor with speeds and accuracies never before seen. This innovatory method the printed industry to ensures perfect and increasing throughput

Improving the Ecosystem:

Formlabs presented an integration solution and acknowledged the importance of postprocessing in fine-tuning 3D-printed components. The Wash and Cure system, in conjunction with customized finished tools, simplifies the process from print to and represents a holistic approach for the user’s efficiencies and conveniences.

This innovative technology will unlock a new era of opportunities across industries, from dentures to automakers, from higher academic institutions to large corporations of manufacture. Form 4 emerges as an engine for growth and transformation by empowering rapid inventions and surpassing the limitations of traditional manufacturing.

Ramnish Sharma, Country Manager, Formlabs India, affirmed that the essence lies in empowering customers with tangible value and fostering a legacy’s trust and innovations. He emphasizes the sensitive nature of Indian markets, stating, “While price’s sensitivities are inherent, they cannot be attributes solely to preferences for cheap products.”

Mr. Sharma highlighted the complex structures of Indian markets. “Valuing is more important to us than just affordabilities.”For example, we are more inclined to invest in products that cost Rs 100,000 if they offer similar value to ones that cost Rs 5,000 and deliver significant value. Delivering unparalleled value to our clients is at the heart of Form 4. We aim for users to get a substantial return on their investments with Form 4 within six months to a year. This market response confirms our commitment to providing long-lasting values and resonates highly.

Speaking of both Formlabs and Imaginarium, Amod Satarkar, Vice President of Sales, highlights the two companies’ cooperative relationship, extensive involvement with end users, and range of applications. He emphasized the importance of Formlabs’ customer-centric culture and the critical feedback loop that Imaginarium and Formlabs have, which affects their research and development efforts!

Mr. Satarkar was elucidating the inexplicable evolution of Form 2 into Form 4 with flawless precision. By emphasizing the pivotal elements, such as SLA virtues, which eased the component printing process and hastened prototyping, Strangely enough, he also identified a critical vulnerability in the capacity to accommodate clients’ speedy tweaks—a vital talent for nimble design procedures.

Mr. Satarkar emphasized the critical role of faster print speeds in facilitating quick iterations and highlighted Formlabs’ creative strategy in introducing LFD (Low Force Display Stereolithography) technology. This revolutionary solution enables users to accomplish numerous design and production goals by addressing prior barriers!

In conclusion, Mr. Satarkar stressed the utmost importance of Formlabs’ dedication towards novel and their capacity to accommodate user necessities, which had, in essence, brought about a fresh epoch of 3D printing effectiveness and nimbleness!

Forefront of Innovation:

Formlabs continues is at heart of innovation in the ever-evolving field of technologyx. Formlabs and Imaginarium are paving the way for an equally promising future with an abundance of upcoming launches and a determined dedication to explore new applications!

In the landscape of technology innovation, Form 4 stands out as a leader, changing the parameters of 3D printing with its persistent dedication to quality and creativity. Every print signifies the start of a new chapter on the road toward a future filled with transforming possibilities and limitless potential!